Industrial 3D Printing Market - Forecast(2021 - 2026)

The industrial 3D printing is used for creating architectural models for tooling and repairing heavy equipment, machinery and robotics in the industries. The 3D printing technology empowers the industries like aerospace and defense, electrical, food and beverage, jewelry and healthcare to scale model quickly and cost-effectively. Among all the industrial 3D model printing technologies, the laser metal deposition is anticipated to witness the fastest growth during the forecast period.

3D printing is the process, wherein three dimensional solid objects are created from a 3D design. It is an additive process in which an object is created by laying down successive layers of material. Globally, demand for industrial 3D printing is being driven by higher accuracy per inch of part dimension, faster printing speed, and introduction of new materials.

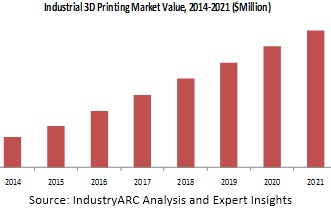

This report identifies the future of global industrial 3D printing market size in for the year 2014-2016, and forecast of the same for year 2021. It also highlights the potential growth opportunities in the coming years, while also reviewing the market drivers, restraints, growth indicators, challenges, market dynamics, market trends, competitive landscape, and other key aspects with respect to industrial 3D printing market.

Geographically, North America dominated the global industrial 3D printing market owing to higher usage of industrial 3D printing in the major industrial manufacturing, aerospace & Defense, and healthcare companies located in the U.S. In addition, financial support from the government and continuous technological advancements are also fuelling the growth in North America. North America is followed by Europe and Asia Pacific in terms of market share in 2017 in the global Industrial 3D Printing. Demand for the Industrial 3D Printing is expected to grow the fastest in the Asia Pacific region due to increasing extensive industrial base, government initiatives, and funding in R&D. Automotive end-use segment dominated the globally Industrial 3D printing market.

This report segments global industrial 3D printing market on the basis of technology, process, material, application and regional market as follows:

This report on global industrial 3D printing market also covers major technologies used in 3D printing as: Stereolithography (SLA), Fuse deposition modeling (FDM), Selective laser sintering (SLS), Direct metal laser sintering (DMLS), Polyjet printing (MJP), Inkjet printing, Electron beam melting (EBM), Laser metal deposition (LMD), Direct light projection (DLP), Laminated object manufacturing (LOM) and Others. The 3D printing material market is also segmented based upon process, which includes sheet lamination, binder jetting, material jetting, and powder bed fusion and direct energy deposition.

The industrial 3D printing market is also segmented into the kind of materials being used for 3D printing as follow: Polymers, Metal and Alloys, Ceramics and Others

- The report is also segmented on the basis of end-use industry in which 3D printers are being used as follow: Industrial Products, Defense, Aerospace, Automotive, Healthcare, Education and Research and Others

- This report has been further segmented into major regions, which includes detailed analysis of each region such as: North America, Europe, Asia-Pacific (APAC), and Rest of the World (RoW) covering all the major country level markets in each of the region.

This report identifies all the major companies operating in the Industrial 3D printing market. Some of the major companies’ profiles in detail are as follows:

- D Systems

- Arcam AB

- Autodesk, Inc.

- Stratasys Ltd

- ExOne

Comments

Post a Comment